It is very hard to troubleshoot amps when one is not actually there to poke around the inside. If it only happens when the amp gets hot, it may be something heating up and desoldering itself. This is fairly common, I've seen it happen in a JCM900 slx and some marshall mg stuff. The solution is the add a bit more solder or a heat sink to dissipate that extraneous heat.

If you don't have experience dicking with amps, I would suggest getting someone that knows how. It will most likely be expensive (typically $50-65/hr + $50 flat bench rate at shops).

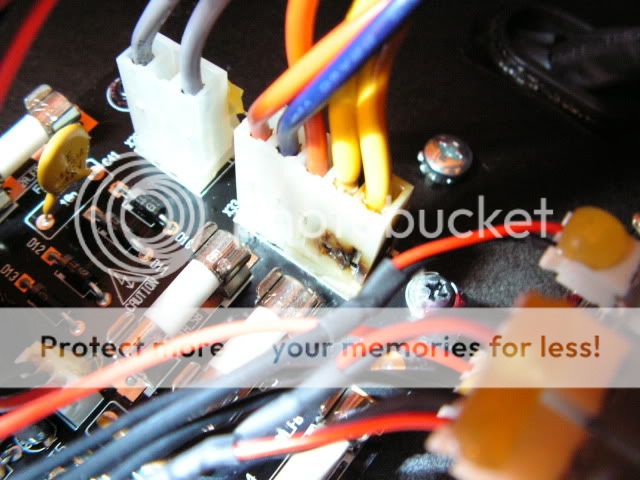

There is a common issue with these amps involving a molex connector that can't handle the current running through it so it melts, causing intermittent then complete failure. One should remove the molex connector, and solder the wires directly to the pcb. This happened to mine before I bought, so I bought it broken for $200 and spent 20 minutes fixing it and have logged more than about 1500 problem free hours since.

Burned molex connector coming from power transformer to main board

Wires from molex soldered to main board

I have no problem with Bugera's build quality. I am working on amps and other music gear all the time as a side hustle and I was actually surprised for how organized and clean the 333xl was. The most problematic amps I have ever experienced were a Marshall JCM900 SLX and JCM2000 TSL. The 333xl is my primary gigging amplifier. I generally play two shows a week in a cover band for 4-5hrs each show. Then have two 4-5hr band practices a week. That's about 20hrs a week.