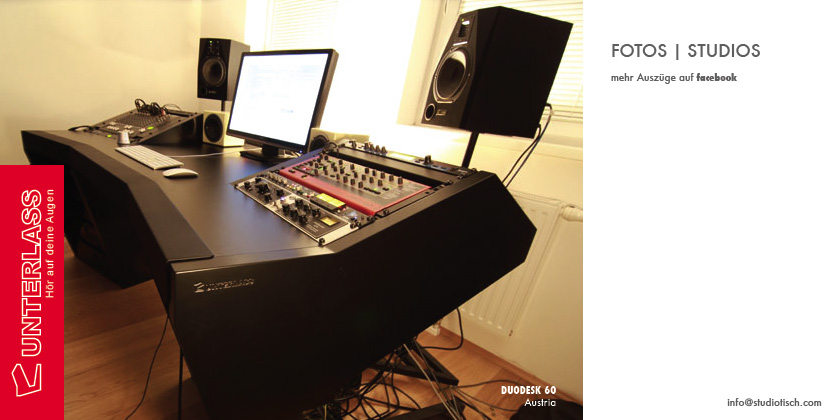

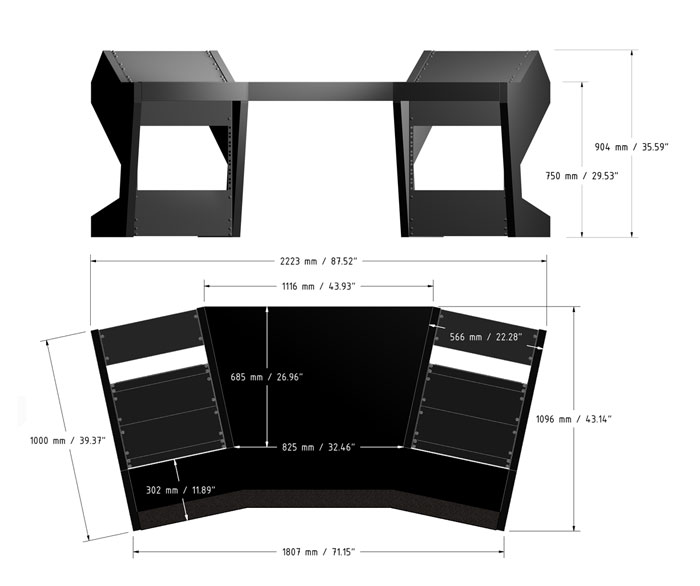

I'm about to DIY a new desk. I was going to build some thing like this:

Does anyone have any thoughts on the angle of the top racks? I think this one is angled at about 20 degrees, I was thinking of bringing it up to about 25. This will make it about 50mm higher at the top but more visible but should still be out of the firing line of the monitors.

Has anyone used this type of desk? Any good?

Anyone have any other thoughts or ideas?

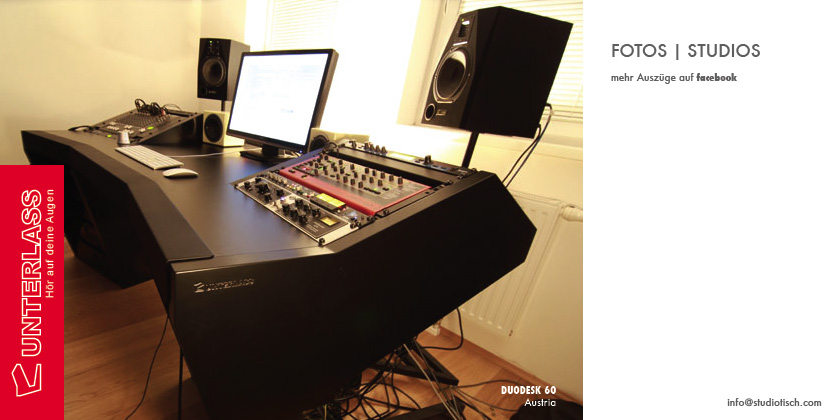

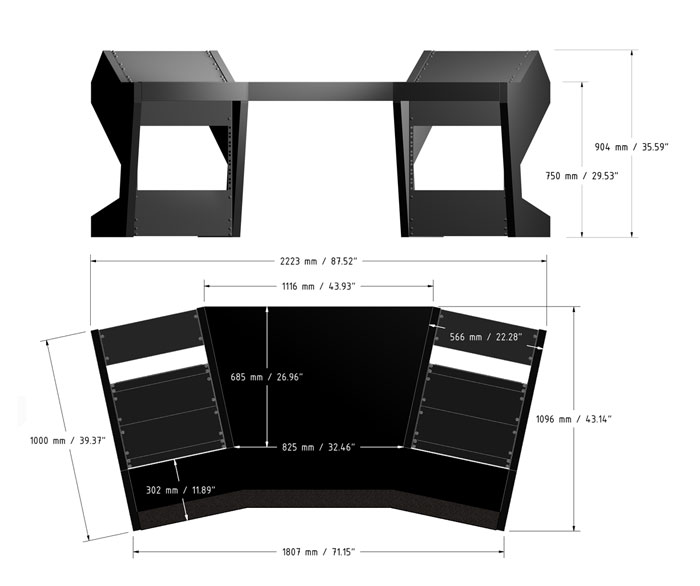

Does anyone have any thoughts on the angle of the top racks? I think this one is angled at about 20 degrees, I was thinking of bringing it up to about 25. This will make it about 50mm higher at the top but more visible but should still be out of the firing line of the monitors.

Has anyone used this type of desk? Any good?

Anyone have any other thoughts or ideas?